Cleo the Cat - Test Item 1G2H3P

Sign In To Add

Register Now

Quick Info

- One Cat

- Meows

- To cuddle.

- Mostly claws.

Quick Start Videos

Manufacturing

Made by JUNG - Since 1972

- US-based Sales

- Stocked and Shipped from the US

- Engineering & Lifetime Technical Support

Specifications

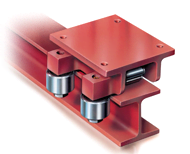

Wheels

Product In Use

Functionality

Product Guides & Documents

JUWAthan+ Wheels

JUWAthan+ Wheels

Superior performance and durability over traditional

polyurethane, composite, or steel wheels.

Wheel Technology & Construction

JUNG machine skates are outfitted with patented JUWAthan wheels. This wheel material is superior in its performance characteristics over any traditional steel, nylon, composite and polyurethane wheels.

Why?

Conventional wheels have to be manufactured in a very dense and hard compound to withstand the high forces exerted by heavy loads. These hard materials have many disadvantages for the intended use.

That is why over many years of testing JUNG developed a material called JUWAthan for the specific use of rolling heavy loads. JUWAthan is based on polyurethane technology but it differentiates itself by a different chemical composition that allows the material to undergo a long baking process in an oven.

In its third generation, the resulting wheel material is softer, tougher and most importantly is highly elastic which is fundamentally different from any other high capacity wheel material available today. (see graph on hardness / durometer).

This elasticity provides the wheel many advantages that target the specific demands of heavy load moving:

Overcomes Obstacles

When a hard wheel material encounters an obstacle, the wheel gets stopped in its track. The wheel then has to go up an over this obstacle.

(Fig. 1) Problems with traditional wheels: Holes

JUWAthan's elasticity allows the wheel to mold around the obstacle to keep on going. So the wheels are more easily capable of bridging particles such as nails, debris, overcoming small ledges, or molding into recesses, countersunk rail tracks or expansion joints. (Qualification: The size of the obstacle must be small in comparison to the chosen wheel /skate size).

Non Floor Marking

Rubber or nylon materials often leave skid-marks on the floor as the material rubs off like chalk. JUWAthan will not create any such markings.

Non Floor Scratching

Scratching of the floor's surface can happen in two ways: A hard material such as steel or a very hard nylon can scratch floors usually during turns or misalignment of the wheels. However, most scratches happen when particles are pressed into a hard wheel such as nylon or even poly. The wheel then becomes embedded with particles which create little bumps and spikes in the wheel over time and with every rotation causes the floor to be scratches. The elasticity of JUWAthan in comparison will mold around any particles and prevents the particle to be embedded permanently which prevents any such problems. The softer material is naturally also much more floor protective.

(Fig. 2) Problems with traditional wheels: Embedded Debris

Non Floor Indenting

Hard wheel materials do not flex and the round shape acts as a spear into the ground. This often can cause indentations in the floor's surface.

JUWAthan will flatten out intentionally under load creating more of a flat contact area with the floor instead of a pointy contact. This also results in a much larger footprint reducing the pressure per square inch between the machine skates and the floor. Consequently JUWAthan will not indent floors.

Shock Absorbent

When a load is first placed onto the skates, the skates must absorb the initial impact which means the wheels must be able to withstand much higher load bearing capacity than the skate is rated for. JUWAthan's elasticity assures that the wheel can absorb the shock and will not crack. Under shock the wheels are formulated to work together with the flexible steel frames (JUNG steel frames are built like a bridge, they can flex and withstand impact forces).

Reliable (No Failure), Long Life Under Constant Use

A wheel can get destroyed from overloading, constant wear, particles embedding, impacts and cracking.

(Fig. 3) Problems with traditional wheels: Cracking & Fracturing

Taking all the factors mentioned together, a JUNG JUWAthan wheel is more reliable and less likely to fail, plus it has a much longer life expectancy because: Due to its shock absorbency, JUWAthan can handle higher impact loading forces and sudden shifts of the center of gravity. The material is less likely to get point-loaded caused by travelling over an obstacle because it will mold around obstacles and it will not be affected by bumps created by embedded particles.

(Fig. 4) Problems with traditional wheels: Bumps

JUWAthan is resistant against particle embedding. These particles often are the number one cause of wheel failures. A particle that gets embedded into the wheel causes the material to tear. This tear - just like on a wind shield - eventually gets bigger and causes the wheel to crack from the inside out.

Roll & Turn Easily

While this is the obvious requirement, at the high weight for load moving many wheel materials such as nylon or standard polyurethane will flatten out or deform into an oval shape under load and instead of rolling will drag behind. This problem is escalated when the load is allowed to rest on the load for longer periods of time often causing permanent deformation to the round shape.

JUWAthan rolls and turns easily even though a softer compound would suggest higher rolling resistance. This ease of rolling is achieved by the inner aluminum or steel core. The wheel actually rolls on the round core while the outside JUWAthan acts like a lining or padding. This also prevents the material from deforming permanently and the wheel always maintains its round shape.

Heat Dissipation

The immense forces exerted onto the wheels causes high temperatures just like heat build-up on car tires during rotation and breaking. This heat can lead traditional wheel material to slowly break down over time and aid in the eventual failure. JUWAthan, being baked in an oven is automatically resistant against simmering heat (see temperature ratings). Furthermore, the wheel's inside core construction is built to work with the axle and frame to act as a radiator, pulling away internal heat to dissipate it externally.

Ball Bearings

Unrelated to JUWAthan, wheels can also fail when cheap bearings get contaminated with sand. JUNG wheels are outfitted with sealed bearings to prevent any contamination. Furthermore, standard ball bearings are not very uniform causing unequal load distribution and high failure rates. JUNG only employs precision ball bearings with low tolerances to assure constant even load distribution.

Core

JUNG wheels are outfitted with aluminum cores on smaller machine skates and steel cores on the larger skates. The more expensive aluminum cores have proven to have the same capacity and reliability as steel but provides the smaller skates with lower weights to be more easily carried and transported plus the aluminum provides more corrosion resistance over steel.

Cost

JUWAthan wheels are made up of a specially formulated and engineered chemical composition. The production process differentiates itself from any other that includes a baking treatment. The wheels are then outfitted with sealed precision ball bearings and protective side caps inside the metal core. Everything from the raw materials used, to the components utilized throughout the manufacturing process makes JUWAthan wheels more expensive but the exceptional level of quality is what separates these Made in Germany wheels from their standard counterparts. While traditional wheels may have to be replaced frequently at a high cost, JUNG rollers keep on transporting heavy loads for many years through daily use.

Conclusion

Machine skates outfitted with traditional nylon, standard polyurethane wheels, composite and steel wheels will transport a load from A to B. These wheel materials are, however, off-the-shelf materials not designed and formulated for the specific use of rolling heavy loads. Consequently users are confronted with a variety of performance problems. Furthermore, this performance rapidly declines with age as the wheels wear out and the user has to replace wheels at a high cost frequently.

JUWAthan-plus wheels on JUNG machine skates are superior to these traditional wheels in performance, reliability, life expectancy and operating cost. JUWAthan-plus is patented and exclusively available on JUNG machine skates.

Main Characteristics

Patented material baked in oven onto core for toughness & elastic performance characteristics:

- Overcomes obstacles easily (wheels mold around obstacles and keep rolling)

- No stop, up & over action required like with other wheels

- Spreads out under weight for large footprint resulting in low floor pressure, low break out & low rolling resistance, low push-pull force and low manpower requirement

- Shock absorbent for impact loading

- Non-floor damaging, non-marking

- Reliable under toughest working conditions

Comparison to Conventional Wheels

Construction

- CORE: Aluminum core on skates up to 12 tons (for lightweight handling) *Steel core on skates 20 tons and over

- BEARINGS: Advanced high-strength precision ball bearings, ball bearings are sealed from both sides to protect against contamination of sand & dirt

- OUTSIDE MATERIAL: JUWAthan+®, bonded into deep grooves in steel/aluminum core against sideways pressures

- HARDENING: Wheels baked in oven for extended period of time

Wheels for Specific Floor Conditions

JUWAthan+ Wheels are designed for:

Wheel Hardness (Durometer)

Our patented wheels are softer, more elastic, more floor protective at higher durability.

* Scale D measured under ISO 2039-2

Chemical Resistability

Resistant: Acetylene, Beer, Butane, Carbonic Acid, Citrus Oil, Ferrous Sulphate, Gasoline, Glycerol, Ink, Methyl Alcohol, Mineral Oil, Nickel Sulphate, Oil, Ozone, Propane, Soda, Sodium Nitrate 10%, Vegetable Oil

Not Resistant: Acetaldehyde 40%, Acetone, Ammonia 20%, Bromine, Carbon Monoxide Hot, Chlorine, Hydraulic Fluid, Iodine, Water over 170°F

Conditional Resistant: Glycol, Saltwater, Turpentine, Waste water.

Wheel Dimensions

The wheel diameter increases with the size of the machine skate. Why?

For safety reasons it is important to keep the load as close to the ground as possible and consequently an ideal wheel size is as small as possible. However, with increasing weight, the rolling resistance of the wheels increases and the ability to overcome obstacles decreases. In other words, a 20 ton load can easily be transported on small wheels but a 40 ton load on the same small wheels will require an unreasonable amount of towing force to pull, the wheels may drag behind and overcoming a crack in the ground or pebble becomes impossible. So the wheel size has to increase in certain intervals to keep the rolling performance the same across any size load.

Differences in Wheel Width

Some skates are outfitted with half-size wheels or a combination of half and full size wheels. Half-size wheels improve the ease of turning plus half-size wheels hold their direction better than full size wheels.

Footprint Differences

Maximum Temperature Ratings

Safe maximum temperature: 170 degrees F

Do not expose the wheels to temperatures above the temperature rating if rolling over hot surfaces such as asphalt, through hot liquids such as water or in hot environments such as ovens.

- Replace the defective product. All defective dollies, skates, and jacks must be returned to Toolwell.

- Replace the defective part. The defective part may be discarded.

- Breaking point: At which point will the skates break?

- How close to the breaking point is the capacity advertised?

- Failure to operate: At which point will the wheels stop rolling & turning?

40+ Years of Proven Quality - Made in Germany since 1972

You've probably heard this statement before:

"We promise the highest quality!"

What exactly does this promise mean?

In our case, it means that our products have been designed, developed, made, and relentlessly improved in Germany for more than 50 years.

Technology

A professional in-house engineering team constantly works to improve our products. We aim to enhance the ease of rolling, durability, and ease of use. This includes making tiny adjustments that may only refine the rolling or lifting friction by 0.1 percent, but these specific modifications accumulate over 50 years and have lead to vastly superior performing products!

We often work on maximizing features that cannot be seen, like heat dissipation of temperature increase during rolling under huge turning forces. All aspects of our dollies, skates, and jacks are analyzed and re-engineered to make the products more efficient.

Testing

In our in-house testing ground, we test materials, parts, and product prototypes. Every new product is then evaluated by professional machinery movers in order to detect weak points in the prototypes or parts. Any discovered deficits are then fed back to engineering.

Manufacturing

Many companies move their production overseas, but JUNG carries on to produce products and components in Germany, and also invests in its manufacturing plant in Germany . We employ robots in the manufacturing to guarantee consistent quality among every single product. Even though other companies nowadays increasingly advertise 'engineered in Germany' - which in fact means built in another place, our products continue to be Made in Germany.

Precision

This means that every product and component is manufactured to precise dimensions and precise shape. It furthermore means that every product and component is precisely the same. When a product or component is exposed to the extraordinary forces of multiple tons of weight, any variance from the exact sizes could lead to product breakdowns.

Case in point: If the diameter between balls in bearings differs even a bit, the forces will be unevenly distributed, which will sooner or later lead to failure. Another example: If the structure is warped even by 0.1 %, then under load, it twists, which may in the long run lead to cracks.

This accuracy can only be attained through state-of-the-art precision manufacturing processes. Low-cost parts can lead to breakdowns, therefore we only employ high-quality components, and each product is exactly the same, and produced to exactly the same production standard.

Conformance to Safety Principles

Our products are put to the test to meet the most recent U.S. safety standard ASME B30.1. This standard specifies the load bearing valuation and safety capacity demanded by OSHA requirements. JUNG skates are really the only load moving skates in the United States that comply with these specifications.

All jacks are tested to comply with ANSI B30.1. All skates can just be tested to capacities of 16 tons. Larger sized dollies and skates cannot be tested, but are made to comply with the same or higher safety standards.

Because of its manufacturing process we can guarantee that each product is identical (and does not vary because it was cut, drilled, and welded by hand). Our products may well be issued with certificates of compliance or certificates of conformity (COC).

Traceability by Serial Numbers

Every product is marked with a serial number. This identifier is associated with the item's material, components, and manufacturing batches. Every part failure can be tracked back to the production batch to determine the underlying cause.

This quality assurance program guarantees that deficiencies are wiped out over the years, so that the products get ever closer to absolutely no defects. No other machine skate and toe jack producer has implemented such an advanced quality assurance program.

ISO

The factory's total quality management system is certified to ISO 9001, which ascertains that customers are provided with continuously improved quality items, and that all products achieve statutory and regulatory prerequisites.

More Expertise Provided to the Customer

Over 40 years of working experience have provided us with a vast technical knowledge base in the field of heavy load moving. We strive to transfer this skills onto our customers, and aim to make this knowledge accessible on our internet site and over the phone.

Customers can call us and discuss their problems with our technical engineers. We have confidence in supporting the potential customer before the purchase, providing support to the client during the operational phase, and providing assistance 10 years after the purchase date.

Our Goal is to Help You in Any Possible Way!

Combining all aspects, our products and customer service are supreme in quality over any other machine skate or toe jack on the market today.

Reliability

Our products are used to lift and transport nuclear reactors and nuclear waste. To a small business this reliability and dependability is equally important as a product failure can be equally devastating. We supply the same product quality to small, medium and large organizations.

The Results of Poor Quality

Similar products sacrifice quality for cost. Copied parts are welded together into a product without any understanding, engineering, R&D and testing capabilities. Unreliable economical variety materials are used building the products, putting your equipment at risk for a break-down. The cheaper construction may result in frames bending from impact loading or axles snapping under load. Customers may constantly need to replace parts to keep the products in operation. Look-alike products may be advertised at higher capacities by eliminating or reducing safety capacities. Knock-offs claim higher capacity while exerting so much weight onto the same footprint that the wheels will drag behind instead of actually rolling.

Our Definition of Load Capacity

Our definition of Load Capacity goes further than just working safely below the break point: The more weight is exerted onto the skates's footprint, the higher the break-out & rolling resistance becomes until too much weight causes the wheels to drag behind, making changing directions impossible. The maximum capacity at which a wheel still turns is limited by the pressure exerted onto the footprint (aside from the component strength). That means a 2 ton rated wheel may stop turning at 1 ton of weight. Be assured that you maintain “easy rolling” and “easy steering” at maximum capacity with our dollies and skates.

Honesty & Trustworthiness

We aim to completely educate our customers about the advantages but also about the disadvantages, considerations and limitations of our products. We do not overpromise.

Professional Engineering

All products are designed by JUNG’s full time engineering team. Besides continuous improvements to functionality and strength, the products are optimized beyond what the customer expects. For example: The dollies and skates are designed for heat dissipation to counter possible weakening over time as high temperatures build up from the enormous friction forces. Internal technology is employed to protect against impact loading and design considerations are given to chemical and environmental resistability. German engineering means test and design for every detail.

State of the Art Manufacturing and Materials

The factory employs state of the art robots in the manufacturing process to assure that every product meets the same quality standards. All products are manufactured in house in Germany. Manufacturing process ISO 9001 certified.We don’t use standard commercial readily available materials. Our materials are specifically formulated, tested and engineered in JUNG’s research and development. Materials are engineered and custom produced for:High Strength Ease of Use Durability under the greatest strain Each component, steel frame and aluminum composition is built with state of the art technology.

Quality Control

All products are function tested after manufactured to guarantee zero defects. Our quality control department tracks all products and components by stamped-in serial numbers to trace any problem to assure zero re-occurrence. A certified quality management program assures a consistent level of quality.

Warranty

Each purchase is a one-time investment in superior quality; each product comes with a five year warranty, and is reliable even after a decade of use within its rated capacity.

| Why Choose JUNG? What Makes These Skates Unique? JUNG products have been copied many times. Those may look the same but certainly will not perform the same. Copies may drag over the surface instead of rolling. It may be close to impossible to change direction unless the cargo is lifted. It may damage the floor. It may be unmovable unless a towing vehicle drags the load rather than rolling it. The skate may fail terribly. It may need frequent repairing. The wheels need to be taken out and replaced very often. JUNG has obtained the technological know-how to develop, test, and manufacture machine skates in Germany during the last 50+ years, with one single goal in mind: To build a machine skate that truly works ... and works ... and works. Our skates will roll with ease, turn with ease, will leave floors intact, perform well under the toughest operating conditions, and have a long life span. They make the job much easier, much faster, and much more reliable for a very long time. As the original and finest skates in the industry, our products have been cloned into look-alikes. While the copied products may look the same - and can certainly move a load from place A to B - how easily and how reliably separates the good products from the bad. When compared with all the look-alikes, JUNG skates are the only ones designed, engineered, tested, certified, and permanently improved from the ground up - instead of being just imitated. They differentiate themselves from the look-alikes:

JUNG products deliver excellence Made in Germany. |

|

|

|

Certifications for nuclear industry All products are function tested by JUNG to verify rated load capacity and assure zero defects prior to delivery. It is a standard requirement to offer a Certificate of Conformity to every customer in the nuclear industry. However, we offer this same certification to commercial customers for a surcharge. The certificate below will be issued on request. |

• “JHS” series Toe Jacks - Certificate-Number: 201006• “G-plus” series toe jacks - Certificate-Number: 201001• “K” series transport trolleys - Certificate-Number: 201002• “S” series transport trolleys - Certificate-Number: 201019• “JKB” series rotating dollies - Certificate-Number: 201007.

| What is needed to move heavy loads with JUNG dollies & skates? Our dollies and skates are outfitted with an advanced wheel material optimized for the lowest rolling resistance while protecting your floors. This rolling technology makes it as easy as possible to push and pull heavy loads. The innovation is derived from 50+ years of continuous testing and product improvement. |

|

Load Weight |

Up to 3 Tons | 3-6 Tons | 6-10 Tons | 10+ Tons |

Manpower Required |

1 person | 3 people | 5 people or towing vehicle (recommended: Vehicle for safe braking) |

towing vehicle |

- Floor conditions: It is easier to move a load on smooth and level concrete surfaces than on rough and uneven ground.

- Weight per footprint: It is less difficult to move a load on a larger dolly/skate than on a small dolly/skate; as more wheels are available to support the weight, there is less weight for each individual wheel to carry. Since each wheel has less pressure placed on it, the load becomes easier to move.

- Size of Wheels: Larger wheels roll easier than smaller-diameter wheels.

- Time at Standstill: Rollers naturaly sag over time when at standstill. This increases the breakout resistance. So the time at rest will impact the force required to start rolling.

- Temperature: High temperatures will cause the roller material to become softer which will increase the rolling resistance.

- and more ...

|

EV Skates are outfitted with a Health Monitoring System:

|

If an electronic issue arises with your battery-powered machine skate, please contact us. A technician will try to understand the problem and decide the quickest way to resolve your issue.

Electrical Support includes:

- Troubleshooting and guided repairs via phone or video conference.

- In-house diagnostics and repairs at Toolwell’s facility.

- Full array of replacement parts available for immediate shipping.

Toolwell stocks a large supply of frequently needed parts including electronic components for all machine skates for quick turnaround on repairs. Rest assured that your repair has priority, and we will work as quickly as possible to return the repaired unit as soon as possible.

Parts are Available for Self-Repair

Mechanical Maintenance:

Mechanical components such as wheels, turntables and bearings, are easily changed by the owner.

Things we do NOT support:

We cannot fix products with body damage. Serious body damage of machine skates can affect the overall integrity of the skate, in many cases replacement should be considered.

- Pressure in a vacuum chamber

- Hot and freezing temperatures in a climate chamber

- Vibration on a vibration exciter

- Shock on a vibration exciter

- Short circuit conditions

- Overloading conditions with twice the current

- Internal and External Damage

Customizations

Standard: Galvanized load wheels, axles and links come standard. |

Option Package "S" - STAINLESS Galvanized frame, galvanized load wheels, stainless steel axles and links. |

Option Package "M" - MARINE 4-layer offshore coating, galvanized load wheels, stainless steel axles and links. |

Accessories and Customizations

Description

Meow.

Meow meow meow. Meow meow, meow meow moew moewwww! Ryawor, meow meow. Purrrrrrrr...............