Boerkey - Machine Roller - Constant use - Capacity 165 tons - MPN AM-H-Cr#6-G

Manufacturing

- US-based Sales

- Stocked and Shipped from the US

- Engineering & Lifetime Technical Support

Quick Info

- One machine roller (Color: Maroon)

- High frequency / constant use

- Permanently loaded Long distance travel

- High safety capacity against point loading and side forces (wind)

- Easy rolling after long standstill under load

- Sideways & radial use (for rotating loads)

- Roller wheels with center routing groove

- Super robust interlocking carbon steel frame construction

- Hardened steel center plate

- Hardened 50CrV4 steel load wheels

- Center chain guide

- Multiple options available (see below)

Börkey Color Coding

Specifications

Customizations

Product In Use

Functionality

Product Guides & Documents

Also-Bought Products

Description

Machine Roller Information

Model Series:

- U.S. Model Series: KM

- Manufacturer Part Number (MPN): AM-H-50CrV4

- Manufacturer product name: Roller Skate – The Super Robusts

Uses:

- For frequent use

- Ideal for use under constant load.

- For rolling long distance

- High safety capacity against point loading (under forward and backward rocking forces) and side forces (such as wind)

- Easy rolling after long standstill under load

- For radial forces (for continuous rotating loads)

Features:

- Bolts on for permanent attachment to load or machine.

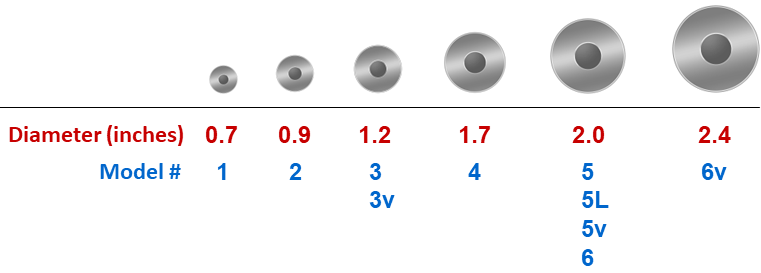

- Model sizes # 1-3v have 4 bolt holes standard. Model sizes # 4-6 have 6 bolt holes standard.

Included:

- Each roller sold separately

Quality Level Classification:

- Ultra-Duty Roller (Levels: Standard | Heavy | Super | Ultra)

Construction:

- Super robust carbon steel construction with interlocking frame design

- Hardened steel center plate

- Super Duty 50CrV4 hardened steel load wheels

- Center chain guide with grooved wheels

Corrosion Resistance:

- Blackened load wheels plus zinc-phosphate coated frame for basic corrosion resistance.

- Additionally, galvanized load wheels, axles and links provide upgraded weather resistance.

- Further stainless steel and marine and offshore coating are available at request for upgraded weather resistance. See Weatherproofing Option Packages

Certifications:

- LRS, ABS and DnV off-shore approved versions available on request.

Applications:

- Used for hangar doors, constantly moving gantry cranes, container unloading, train systems, used to rotate telescopes, to enable tubular rotation, for ship building, and machine engineering, for guidance of components.

- Rollers can be used up-side-down as a conveyor, when the Rollers are stationary while the load is moving.

Use in vertical position:

- Check with the manufacturer before selection of Rollers for use in a vertical position.

Manufacturer:

- Manufactured by Börkey

- Made in Germany

Other specs:

- Maximum safe speed: 16 feet per minute.

- Minimum turning radius: 10 feet.

- Rolling resistance (on solid surface such as steel)

- Sizes # 1-3v: 5-7 % of load weight

- Sizes # 4-6: 3-5 % of load weight

Other Important Information:

- Individual machine roller capacities are calculated based on moving the load across a steel surface (all wheels are touching the floor and the load weight is equally divided across the roller footprint). When using 4 (or more) rollers, load may rock on uneven surface, increasing load weight applied to any roller. Therefore, select suitable rated roller capacity carefully.

- Börkey Machine Rollers are made to run on a solid strong surface such as steel. Operating the machine rollers across concrete floors – especially repeatedly along the same path - may damage the floor. For best results use on suitable tracks, e.g., crane rails or steel beams.

- The track or floor surface is vital for the safe transportation of the load, not just the carrying capacity of the Roller. Movement on tarmac and concrete is restricted, and the rollers should never be used on uncovered tile. For best results on tile, concrete, or tarmac we recommend putting a steel plate of a minimum of 0.4-inch thickness underneath.

- Machine Rollers with larger diameter wheels will roll more easily than those with smaller wheels. Problems such as high rolling resistance on certain surface types such as concrete, or resulting floor scratching, can be avoided by choosing roller models with a larger load wheel diameter. Consequently, if moving across concrete floors, size #3 rollers (1.2 inch/30mm wheel diameter) or larger should be used.

- Precautionary measures must be taken for use on inclines to avoid run-away loads!

- When mixing and matching machine rollers (or different load supports), keep the load at same loading height. Otherwise rollers will tip and become point-loaded.

Optional packages available:

For weather proofing the machine rollers are available with the following add-on option packages:

- Option S - Frame galvanized, Load wheels galvanized, Axles and links in stainless steel for longer-term outdoor use.

- Option M - Frame coated with 4-layer marine & offshore coating, Load wheels galvanized, Axles and links in stainless steel for offshore and maritime use.

How Does This Machine Roller Differ From Other Börkey Models?

Every Börkey machine roller starts with a “Made-in-Germany” - interlocking solid frame design, however, each component can be upgraded to improve certain performance characteristics allowing a perfect configuration for any application.

The standard Börkey machine roller features the Solid frame construction with hardened steel load wheels. These Machine Rollers are specifically made for installation of machines & material handling where the rollers are only loaded for a short time and roll short distances. (Models KK, KN and KC).

Hardening the center plate additionally significantly improves the ease of rolling after long standstill under load. These Robust Rollers are made for loads that sit longer on the dollies, roll a short distance but must roll after an extended period of inactivity such as during construction. (Models KB and KA.)

Further upgrading to the Super Robust construction provides superior strength and stability against torsion and fatigue over time under extreme loads and extreme rolling forces. Using load wheels manufactured from hardened 50CrV4 steel creates a higher safety capacity against point loading (rocking) and side forces (wind). The addition of a “channel”-type chain guide to the center plate keeps the load wheels in a track preventing wheels from scraping against the walls and prevents chain damage. These Machine Rollers are specifically made for permanent load carrying, where loads sit on these rollers for many years, must roll a long distance, and must be safe even when subjected to rocking or side forces. (Models KS and KZ.)

By adding a groove into the middle of each wheel and outfitting the center plate with a “center”-type chain guide to run inside the wheel groove wear on the wheels is completely eliminated. This allows the machine rollers to be used frequently. (Model KM)

All machine roller models have “blackened” wheels plus a zinc-phosphate coated frame to provide a durable basic level of corrosion resistance. Galvanization of wheels, axles and links improves the corrosion resistance significantly. (Models KB, KA, KS, KZ and KM). Additional options such as galvanization of frame, stainless steel components and marine & offshore coatings are available. (Models KS, KZ and KM).

Guiding Casters are available in many variations.

Guiding Casters are available in many variations.